CASE STUDY 2

Hybrid process for water recovery and energy harvesting from industrial brines

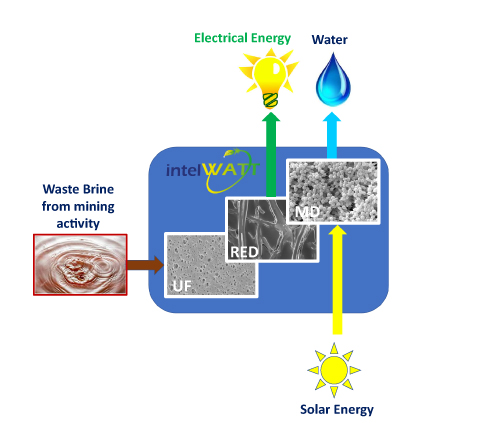

The intelWATT’s Case Studies 2 (CS2) aims to valorise a brine stream from mining activities by harvesting salinity gradient power (SGP) by reverse electrodialysis (RED) and recovering deionized water by membrane distillation (MD) in an integrated system exploiting renewable energy sources (solar energy).

In a RED process, cation exchange membranes (CEMs) and anion exchange membranes (AEMs) are alternatively aligned to form a series of adjacent compartments: high concentration compartments and low concentration compartments. When the compartments are filled with the respective feed solutions, low salinity solution (LSS) and high salinity solution (HSS), an electrochemical potential is generated due to the difference in a salinity gradient. When an external load/electrical consumer device is connected to the electrodes, an ion flux across membranes is initiated, which is converted into electrical current mediated by redox reactions at the electrodes, resulting in control of the HSS and LSS to harvest SGP.

Membrane Distillation (MD) is a non-isothermal membrane separation process that refers to a thermally driven transport of water vapour through a non-wetted porous hydrophobic membrane. The driving force is the vapour pressure difference between the hot and cold sides of the membrane. The hydrophobic nature of the membrane prevents liquid solutions from entering its pores due to the surface tension forces.

The objective of the CS2 is to demonstrate at Technology Readiness Level 7 (TRL 7 – system prototype demonstration in operational environment) the implementation of maximum water reuses and green energy conversion in a crucial EU and global industrial applications such as mining.

The location of the integrated RED/MD pilot plant of CS2 is Castellgalí (near Barcelona, Spain), which hosts the intersection point of a brine collector, the biggest in Catalonia, which picks up the brines from different salt mining industries in the Barcelona’s area.

The basic idea of the CS2 is to demonstrate the possibility to valorise this waste brine as renewable energy and water source.

The pilot plant will comprise the following sections: a pre-treatment unit to reduce potential membrane fouling; a RED unit for SGP harvesting by converting the chemical potential difference between two waste streams with different salinity into electrical energy; a solar-assisted MD unit that will operate on the mixed solutions outgoing from RED in order to recover distillate water.

A key part of the case study will be the smart process control towards improving the pilot performance. Tailor-made sensors and automated decision-making mechanisms will optimize the process conditions in real-time.